Consider these troubleshooting tips for a successful sprayground

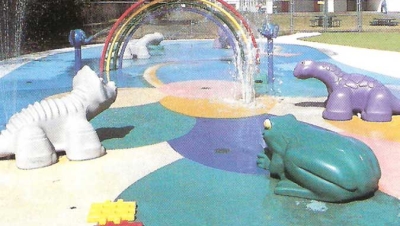

We all know how active and creative children are, and how easily these qualities can lead to injury. aquatic playgrounds are designed to be unsupervised play environments. hile a supervised environment can stop children from playing too aggressively, properly designed space and safe equipment can help minimize hazards and accidents that occur.

“Safe, high quality designed equipment will keep kids injury free,” says Susan Baker of Waterplay Manufacturing Inc.

The most important factor in both unsupervised and supervised environments is ensuring the equipment is made to the highest playground standards. t is important that people consider that this equipment is for children, so it has to be made extremely safe. Much of the information that follows may seem rudimentary to some, but it’s definitely worth considering:

• Spray nozzles should not protrude from any piece of equipment. They should be recessed into equipment surfaces.

• Ground sprays should be flush with the surfacing of the park. watch for products or spray pieces that could cause potential tripping hazards. Children often close their eyes when running through the spray. my sprayers not flush with the ground would be hazard.

• Ensure the equipment purchased s non-climbable. Children will climb any equipment they can wrap their hands around. Look at products offering thick piping to discourage any kind of climbing.

• Watch for products that may have potential to pinch little hands or trap fingers. his is especially important with products that move or rotate.

“When we did a customer survey in 2000, the injuries most reported were minor scrapes and scratches due to slipping on the wet surface,” Baker said. “A rubberized surfacing can help decrease these injuries.”

The problems that occur in an aquatic spray park may be slightly unexpected if you do not already have experience with aquatic playgrounds. The biggest problem organizers run into once the park is open is too many kids in the park. “Aquatic playgrounds are so popular that kids will come from all over just to play in one,” says Baker.

This unplanned increase of use can lead to drainage problems as water is flowing constantly.

Another problem is familiarity with the concept of aquatic play areas. s more and more communities put in spray parks, it becomes easier for parks and recreation directors to get support from local governments and approval to build one. This is the time to become aware of potential problem areas—and avoid them accordingly. Here’s a hit-list of things to be aware of:

• Overspray problems may be caused by the equipment being located too close to the edge of the park.

• Plumbing and electrical problems could potentially occur because of inexperience or non-certified installers.

• Project coordination may be lacking, especially when no one is assigned the role of project manager.

• Contractors may try to save money by using non-specified mechanical equipment or by trying to install equipment that the park was not designed for.

The solutions to these potential problems can be resolved by prior planning. Assign a project manager o to oversee the entire coordination of the project. This individual should come from the technical ranks and is ultimately responsible for the overall installation. his person should be present every step of the way, with a project checklist in hand to help ensure proper installation of the equipment.

“Qualified designers and installers are the keys to a successful park,” says Baker. By selecting a project coordinator/manager and in turn finding an experienced designer, you will be able to avoid many problems that can occur. An experienced designer understands how to eliminate problems with drainage and overspray. ask the manufacturer to recommend a designer if you can’t find one. Always adhere to the advice of the manufacturer. They know best where and how their equipment should be installed. A manufacturer knows the limitations of equipment and how to get the most play out of each piece.

“It is imperative that a certified plumber and electrician install the products,” Baker adds. “Aquatic playground equipment is not complicated, but improper installation will affect its ability to operate.”

Also be sure to follow the project checklists provided by the manufacturer. These checklists provide step-by-step installation instructions and are designed to ensure a smooth and proper installation process. ll aquatic playground equipment is manufactured differently. Anchoring systems are different, spacing requirements are different, pipe size is different, and control systems are different. Allowing a contractor to substitute a product for something the park was not designed for will affect the overall success of our park. See the information that is provided by the manufacturers of the equipment. Again, manufacturers know the specifications of equipment and how to use it to its fullest extent, without endangering participants or spray pieces. The design of our park should be modified o fit the equipment that is being installed.

It is a good idea to inspect your park at least once a week regardless of where you live. All component surfaces should be checked for visible signs of damage while the performance of all nozzles should be observed for changes in display. Maintenance crews want to be sure the park is being used to its full potential and the area is free from any debris or potential hazards.

Most spray park equipment has a layer of powder coating, which provides a defensive barrier between the equipment and corrosive substances. This coating requires regular polishing and cleaning to maintain its original appearance and prevent water build up in creviced areas. It is recommended that a good coat of paste wax be applied to all spray park equipment. The wax layer can help prevent water spots from forming and also prevent spray paint from sticking to the product in the event of vandalism.

Vandalism, by the way, can spread through the park once one piece has been defaced. Vandalism works like cancer—spreading, feeding on good equipment—if not treated with a good dose of paint and protection. So, if and when vandalism begins, treat immediately to deter following acts.

Certain procedures should also be followed to preserve the water features over the winter months. In order to prevent freezing, the water pipe lines should be completely blown out. A gravity drain cock, typically featured in the water distribution system, can easily drain the water from the lines. To prevent corrosion, nozzles should be replaced with blanks or plugs, but only after the lines have been blown out. A final step in the winter shut down process is the reprogramming of the spray park controller to ensure the park is not operational after the spray park season closes.

understanding ow to properly design and install the products is the number one solution to solving problems before they become an issue. creating a partnership with the manufacturer and reading all their information before beginning such a project will help as well. Talking to other aquatic playground owners and discussing their experiences can only improve your spray park design. Who knows, they may be able to stop you from making a few blunders they made.

Add new comment