Curtis Stoddard has been a playground contractor for over thirty years and has constructed thousands of playgrounds across the Intermountain West. He co-founded the International Playground Contractors Association (NPCAI) and has been involved with ASTM International (ASTM), the National Playground Safety Institute (NPSI), and the International Play Equipment Manufacturers Association (IPEMA). Curtis wrote the curriculum for the NPCAI Construction School and has been an instructor at the school.

PPM: Curtis, you have been in the industry a long time. Can you give us a short history of playground construction?

CS: Early playground structures were built by local welders or carpenters. This gave us many creative and unique playgrounds, but durability and safety were sometimes not present. Early manufacturers of playground equipment produced small individual play components that shipped and assembled easily. Playground equipment then evolved into component structures that allowed for multiple designs and bigger structures. By the early 1990s most local playground equipment designers and builders were gone (hard to keep up with the safety requirements). Today most playground construction is done with pre-manufactured equipment that requires assembly, not welding or nailing. Of course, the other difference in the evolution of playground construction is safety guidelines and standards. Today’s builders have many rules to follow.

PPM: So defining a playground builder, would you say it takes a trained professional these days?

CS: I personally believe (along with many states’ governments) that playground builders should be licensed, insured, and certified. States and cities have their own requirements for building public playgrounds. These requirements should be followed.

PPM: Why types of insurance should a contractor have?

CS: Any contractor doing public work (or private) should protect himself and his clients by having the appropriate insurances. There are many kinds of insurance, but liability, workers’ compensation, and vehicle and machinery insurances are the minimum coverages a contractor should have.

PPM: How do playground builders become certified?

CS: There are currently only a few recognized certification programs. The National Recreation and Park Association (NRPA) has the Certified Playground Safety Inspector (CPSI) certification, and some manufacturers offer a factory trained and certified installer program for their products. Not all companies offer this certification.

PPM: You make it sound like playground construction is a specialty like plumbing or electrical.

CS: Look, anyone can build a playground. But not everyone can build a playground correctly. I have inspected playgrounds built by general contractors that were not built correctly. I have inspected playgrounds built by Boy Scout troops that were constructed perfectly. Building playgrounds is a specialty that requires a special process. You have grade issues, layout, footings, assembly, concrete, wrap up, and this is all done with pre-finished materials that you cannot scratch or scrape! There is so much that goes into a project to pull off a successful build.

PPM: Describe what you mean. What are the important elements that go into building a playground successfully?

CS: Playground builders need to know the guidelines and safety standard requirements for playground equipment as well as the surfacing that is installed below it. They also need to have general contractor knowledge and resources and have experience in construction. These are all crucial to a successful playground construction project. If adherence to manufacturers’ installation details along with adherence to ASTM standards and CPSC guidelines are to be considered to be important, then the last parties responsible for the implementation of these objectives, the contractor and installer, are vital to the success of the playground project.

PPM: Are there other skills a playground contractor should have?

CS: I could go on forever about the skills a good playground contractor should have. From pre-planning and mobilization to job completion, a contractor is presented with many challenges and must be organized and efficient. He must be a problem solver and have good people skills. Using qualified and experienced playground builders is smart business and good risk management.

PPM: Tell us some technical aspects of playground construction.

CS: There are basically three areas of playground construction. The first is basic land and site infrastructure, which includes topography issues, drainage, borders, parking, access, trees and shrubs, and site amenities. These are things common to many types of construction.

Second is playground equipment installation, which is a specialty. If you do not like putting bikes together on Christmas morning or putting today’s kit furniture together, then do not become an equipment installer. Installation of playground equipment requires strict adherence to detailed drawings. Many aspects of playground equipment installation are closer to mechanical work than carpentry.

PPM: Why do you say that?

CS: Any given play structure has thousands of bolts and parts. Putting the right bolt in the right spot is critical to the strength and longevity of a product. Following directions is a very technical part of installation. A builder must be aware of playground hazards, such as crush and shear points, entanglements and impalements, entrapments, sharp points, corners and edges, suspended hazards, and tripping hazards.

More contractor responsibilities include equipment heights for swings, slides, and overhead events, footing sizes, and adherence to standards and guidelines, such as CPSC 5.1.1: “Platforms should be generally flat (i.e., ± 2° of horizontal). Play and Playground Magazine has included a list of CPSC Guidelines that apply to playground equipment safety on page 26 in this issue.

PPM: What is the third area of playground construction?

CS: Third is surfacing. While loose fill products are easy to install, there are many technical requirements for accessibility that fall under regulations set by the Americans with Disabilities Act (ADA). The same laws and guidelines apply to unitary surfaces along with the technical requirements of that particular unitary product. Pour-in-place surfacing installation can fail due to many issues such as mixing, temperature, application, and curing. Tiles can expand and contract creating huge problems if not installed correctly.

PPM: With all the technical knowledge you are describing for playground builders, it seems you would not support community build construction.

CS: Well…with playground construction having been my business, I support a level playing field, and I support licensed, insured, and certified installers. That being said, if the licensed, insured, and certified requirements are being met, a community project can be successful.

When I step outside of my construction business, I support properly supervised community built playgrounds 100%. In the next article, Jay Beckwith describes the beauty of community built projects.

PPM: What is the future of playground construction?

CS: Playground equipment is getting higher, has more moving elements, and some manufacturers are introducing electronic devices into the equipment. This means that contractors’ skills must grow with the playground equipment industry’s new trends.

Taller play equipment means different installation equipment, different safety rules, and a different thought process during construction. It’s the same with electrical – a whole new set of rules and skills are involved in the installation of these play components that require electronics.

If playgrounds are regulated nationwide the way they are in California, and if hard stance surfacing requirements are put into place, the playground construction industry will need to step up to fill the owners’ needs of compliance with stiffer safety and accessible requirements.

PPM: What do you mean by hard stance surfacing requirements?

CS: Well, the unseen part of the future of North American playgrounds is surfacing. Safety and accessibility clash. Safety requires a soft bouncy surface; accessibility requires a stiff stable surface. How these two eventually work together still remains to be seen. It may be that surfacing becomes the most expensive and technical part of a playground project. At any rate, surfacing installation is sure to remain a big part of playground construction.

PPM: Let’s talk a moment about what you enjoy most about playground construction?

CS: I have always been a builder, so building is in my blood. I do like the whole process from start to finish.

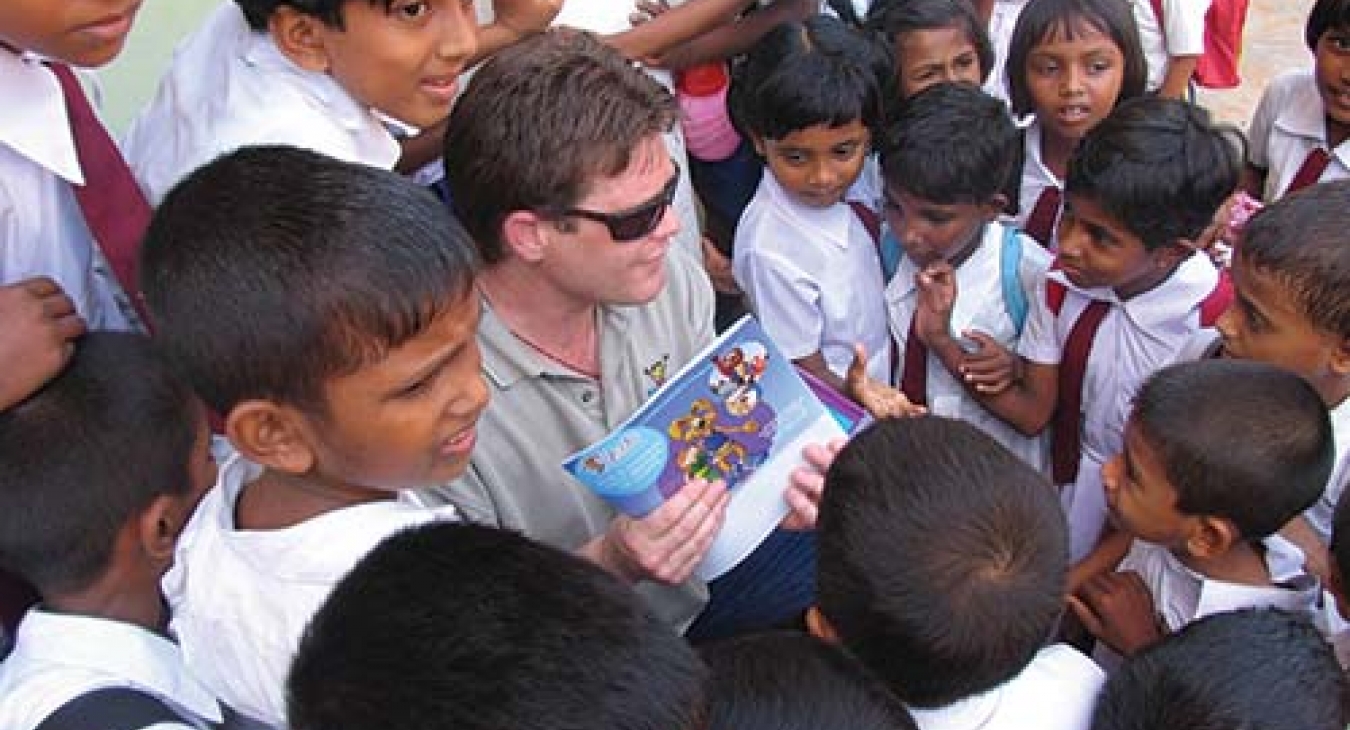

Otherwise I have enjoyed the travel. I have been everywhere in the four states that I work in and have met thousands of wonderful people and children. I have built playgrounds at the Grand Canyon, Yellowstone National Park, Glacier National Park, Zion’s National Park, and so many of the cities and small towns in between. I go into these communities and spend a few days or a few weeks and have grown to know these towns, roads, mountains, and deserts intimately. And to see the big smiles on excited children’s faces always warms my heart. It has given me an opportunity to play…today and every day!

Add new comment