The Good, Bad, and Ugly

Concrete footings for playground equipment are one of the most important issues when constructing play equipment. The United States Consumer Safety Commission’s Handbook for Public Playground Safety notes, “When properly installed as directed by the manufacturer’s instructions and specifications, equipment should withstand the maximum anticipated forces generated by active use which might cause it to overturn, tip, slide, or move in any way."

"Secure anchoring is a key factor to stable installation and because the required footings sizes and depths may vary according to equipment type, the anchoring process should be completed in strict accordance with the manufacturer’s specifications.”

Playground equipment has a lot of stress and pressure on it–think 10 little monkeys jumping on the bed. With all the weight, movement, and other stress factors like weather and gravity, a proper footing is essential to the safe use of playground equipment.

The basic materials of concrete footings are cement and water. Some people may think that these two are the same thing, but in reality, cement is but a part of what makes concrete.

A powder substance known as Portland Cement is mixed with rock aggregate, and when water is added a chemical reaction called hydration occurs. The mixture is then poured and spread to the size and shape of the pre-designed form. When it hardens, it becomes what we call concrete. In other words, cement is the binding agent in concrete. A stiffer mix –a ratio of less water added to the mix – makes for stronger concrete when dried. If construction occurs in cold temperatures, chemicals can be added to the concrete mixture to help it cure faster.

Soil & Footing Relationship

When building a playground the soil in the footing areas should be inspected. Often such inspections are overlooked where playgrounds are concerned. Unlike building footings with hundreds and thousands of pounds of weight and stress, playground equipment footings usually do not require professional assessments. However, having a general knowledge of the bearing strength of different types of soil is important to the overall footing strength. Disturbed soil–dirt that has just been excavated--for example, once dug up will mix with air and lose its density. Loose soil has less bearing capacity than packed soil. When inspecting soil at a playground construction job site, a penetrometer--a spring-loaded handheld device that estimates the pressure soil can resist, usually provides an adequate measurement of a soil’s ability to resist movement in and around a footing. Always compact loose dirt and recognize the potential for unpacked and loose dirt to cause damage or stress to playground equipment.

Preparing the Footing

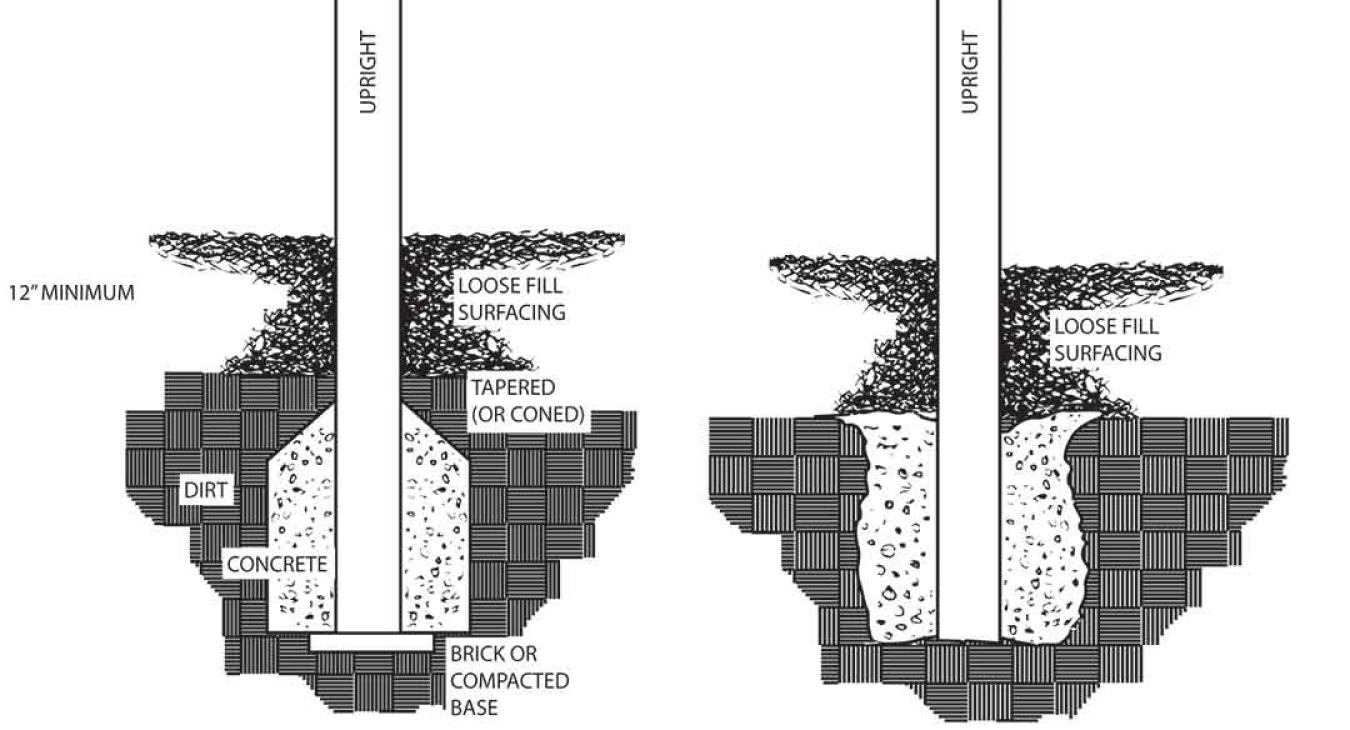

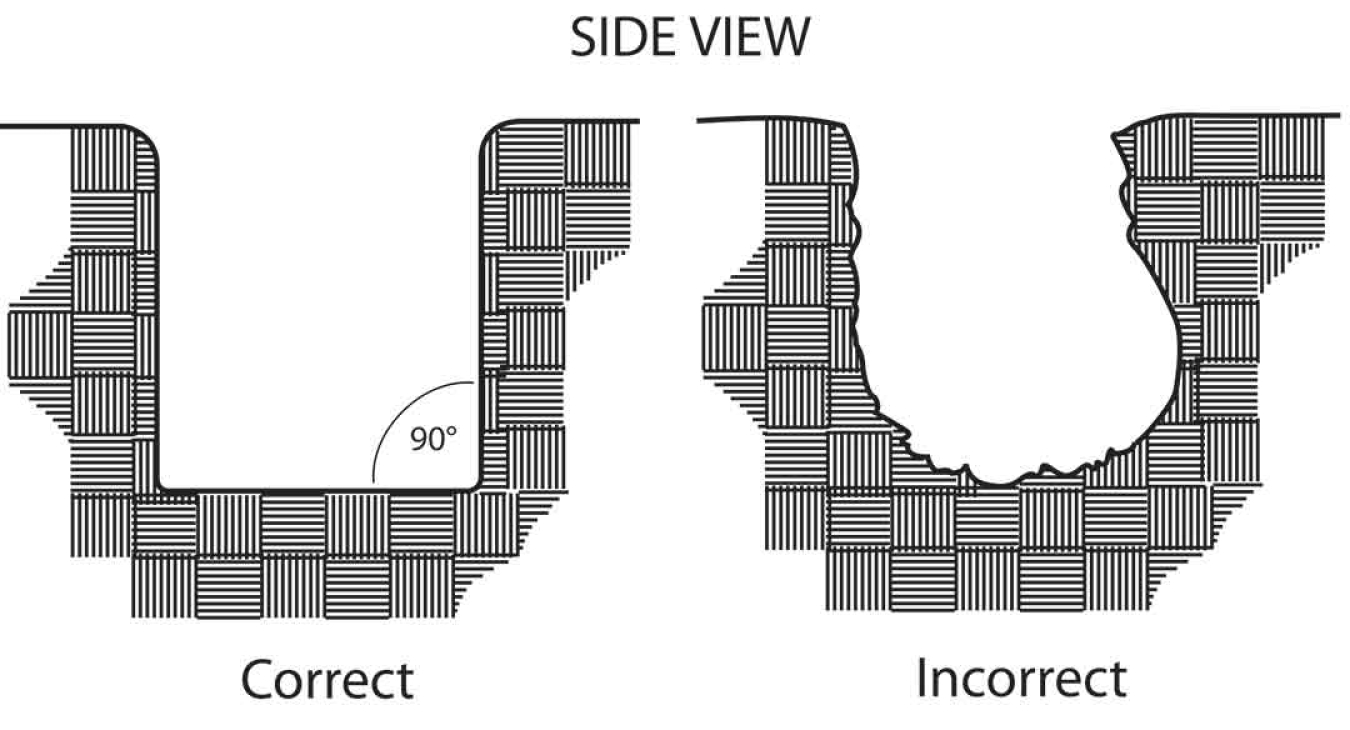

Footing sizes should always be a minimum of the manufacturer’s recommendations. Loose soils may require exceeding the manufacturer’s recommendations. As the earth around a footing hole is most often used as the actual footing form, it is important to ensure the soil is solid enough to fill this role. If it is apparent that the footing walls will not support it while digging, cardboard tubes or wood forms may be used.

Footing walls should be dug straight down, with a flat bottom, to form a 90-degree angle with the bottom and side of each hole.

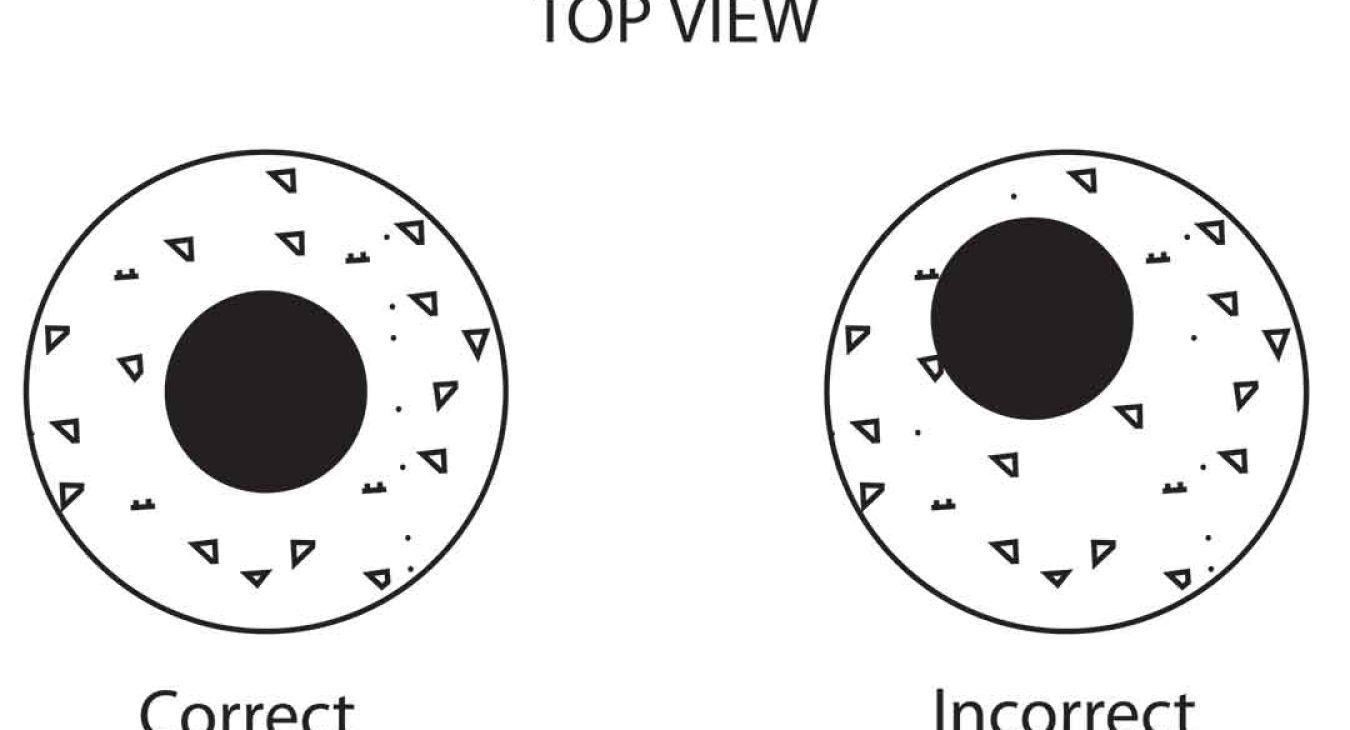

Each upright or play component placed in a footing hole should be centered so an equal amount of concrete sets on each side of the post.

Placing Concrete

When pouring concrete in the playground footings you may need to wheelbarrow or pump concrete into the holes. It is important not to drop large loads of concrete into a hole at one time, as this may move the uprights or components out of plumb and level.

Fill the hole evenly from all sides and stop two inches down from the top of subgrade. If you are using loose fill surfacing, this will prevent the concrete from becoming a trip or fall hazard if the loose fill material is dislocated.

Slope the concrete down and out from the post to prevent water from sitting around the post and causing deterioration. Cover the concrete with two inches of dirt.

This is basic playground footing information that all playground builders and owners should know. Be sure to check an installer’s footings before they are covered up with fall surfacing material and the playground is completed. Footings are the foundation of a playground. They must be strong and durable.