Playground surfacing takes a lot of abuse; thousands of little feet are constantly pounding, pushing, kicking, and grinding at the surfacing.

Occasionally, through sloppy installation, playground surfacing takes a pounding and gets ruined before children even get a chance to play on it. Quality of installation is one factor to consider when selecting loose-fill surfaces. It requires a proper depth of material and installation to function as the manufacturers intended.

Adequate safety surfacing is determined by two factors: impact attention and head injury criteria (HIC). These are both formulas developed from when a test computerized head form falls on the surface.

Impact attention and HIC readings are determined by the type of surfacing, quality of the surfacing product, and depth of the surfacing. For example, it takes twelve inches of loose-fill or tub ground wood surfacing (engineered wood surfacing) for a twelve-foot fall height. If the surfacing falls below twelve inches, you will not have the required impact attention and HIC values and need more depth. If the surfacing is filled with gravel, dirt, fabric, or other impurities, you will not have the required critical fall height because these

items are not as resilient.

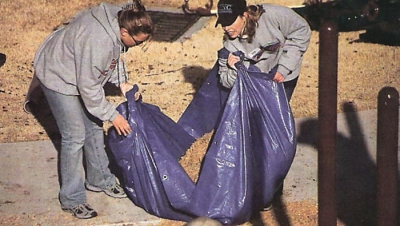

Take a look at the photos that accompany this article. The contractor decided it would be easier to install the drainage, fabric, and surfacing before installing the playground equipment. When the play equipment installer arrived, the contractor jumped on his tractor and proceeded to move the wood surfacing, creating a mix of gravel, fabric liners, and engineered wood surfacing mixed together. Essentially, the contractor ruined the engineered wood surfacing, which is a costly mistake.

Mixing the gravel and fabric with the wood contaminated the product and reduced the impact attention and HIC values. The exposed fabric liners pose a trip hazard and eliminates the intended function of separating the wood surfacing from the ground. This mistake will eventually lead to the premature decomposition of the wood product, and children are likely to pull at the fabric, which may create another safety hazard.

This example makes it clear that the protective surfacing should be installed after the play equipment. If equipment is being added to an existing area, care should be taken (with hand tools, do not use heavy equipment) to keep the wood surfacing clean and free of impurities. Care should be taken with the fabric liners, so they can be reinstalled flat on the ground.

Loose-fill surfacing also requires daily maintenance, especially in high-traffic areas. Examples of areas that need daily replacement are at the bottom of busy and high traffic areas. Examples may include: the bottom of the slides, swings, fireman’s poles, or other places where surfacing is moved around by children's feet. A common solution to this problem is installing rubber mats under some of the surfacing at these high traffic points.

Loose-fill surfacing also needs to be replenished regularly. The frequency of replenishing depends on the type of product, amount of use, weather, and other factors. Correct depths of surfacing should be replenished annually at a minimum.

Surfacing is one of the most important aspects of a safe play area as approximately 70 percent of all playground accidents are falls. result from falls onto the surfacing below. Do not overlook the installation and maintenance of loose-fill surfacing, since it very well may be the most important aspect of safety on your playground.

Add new comment