ASTM International

What if any serious injuries have we reduced over the past 30 years?

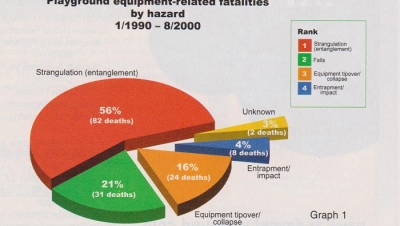

For more than 30 years the U.S. Consumer Product Safety Commission (CPSC) has been gathering and analyzing injury data. During this time, falls to the surface have been the leading cause of playground injuries requiring medical attention. Fall-related injuries continue to be one of the four leading causes of death on playgrounds. The debate on whether the percentage of injuries due to falls has increased or decreased since the CPSC began analyzing injury data will continue but we cannot deny falls are still the number one cause of injuries requiring medical attention.

For the past 30 years playground safety advocates have used the best information available at the time to support the evolution of our standards and guidelines. The ASTM International (ASTM) F8.63 Subcommittee (the Subcommittee responsible for the impact attenuation test method standard F1292) was asked by the CPSC to establish a test method and minimum acceptable performance threshold to minimize the likelihood of serious head injuries on playgrounds. They took the recommendation for the maximum threshold of 200g and 1000 HIC from the CPSC. The rationale used to establish these first performance thresholds continues to be used by all international playground standards organizations. The injury statistics indicate no measureable or significant impact on the frequency or severity of fall-related injuries.

ASTM Subcommittees continue to debate and discuss what should be the minimum acceptable impact attenuation performance requirements. Both the F8.63 Subcommittee for playground surface systems and the F15.29 Subcommittee for performance requirements for public play equipment continue to apply the same rationale for the surfacing performance generated by the F8.63 Subcommittee. I believe this debate has a significant impact on the outcomes of the ASTM F1487 Standard in relationship to the scope of the standard.

What are our Standards Developing Institutions trying to accomplish?

ASTM F15.29 Subcommittee is currently working on redefining its overall performance requirements as we begin to address known hazards and resulting injuries identified in the ASTM F1487 Standard’s introduction and scoping statement. There are many types of potential impact hazards on the playground. One example of a performance requirement established to reduce the likelihood of serious suspended component impact injuries is the new Dynamic Swing Impact Test Method and Impact Threshold. ASTM F15.29 addressed this form of impact hazard related to suspended components (swing seats) by reducing the impact threshold to a maximum of 100g and/or 500 HIC.

When it comes to other impact-related injuries such as falls to the underlying playground protective surfacing, there has been no action taken to reduce impact thresholds in the current ASTM F1292. Understand the F1292 scope has always historically been to minimize the likelihood of a serious head injury. There has been no claim to reduce or eliminate the likelihood of long bone fractures. In fact, no standards developing institution including the CPSC has ever claimed to eliminate serious long bone fractures.

CPSC did recognize the different relationships between G-Max and HIC and decided to utilize both measures in the development of a performance standard and test method for fall-related playground injuries. While HIC is related to head injury, the use of g forces has been more closely related to other types of impact injuries such as long bone fractures. All other international standards for playground surfacing performance testing use only the laboratory test results and the 1000 HIC as their performance threshold. Knowing what I have learned about surfacing and surfacing performance in the field, I do not feel comfortable with the current amount of information these standards provide as industry recommendations to guide those responsible for maintaining the minimum requirements for impact attenuation surfacing performance and accessibility within the use zones and accessible routes.

There is one rather seemingly harmless, yet troubling, requirement within the ASTM F1292 Standard. It states the owner/operator has the responsibility to maintain the surface in compliance throughout the life of the playground or take it out-of-service until it can be brought into compliance. For the time being, the existing standards within the purview of these two Subcommittees continue to hold the owner/operator responsible for meeting the minimum requirements of all these standards after installation. If the surface is found to be out of compliance, they are to take the playground out-of-service until the equipment or surface within the accessible route or use zones are brought into compliance.

There appears to be a performance conflict related to these two ASTM Subcommittees which occurs immediately following a serious fall-related playground injury. When someone falls off a piece of playground equipment, who is to blame? Is it the designer/manufacturer’s fault for creating too challenging a design or is it the lack of adequate impact attenuating surface performance?

There is a general lack of understanding by owner/operators as to what these playground standards say when it comes to everyone’s responsibilities. There needs to be some better clarification of responsibilities to clear up some of this confusion as to the specific responsibilities of each party involved in the management, design, layout, installation, inspection, maintenance, repair, and ultimately replacement of each and every public playground.

If the equipment manufacturer and owner/operator are to be held responsible for injuries sustained as a result of the equipment design or the surface system performance as spelled out in the ASTM Standards in question, then those responsible for producing playground surfacing systems and playground equipment must be responsible for, and required to, provide all information necessary to assist the playground owner/operator’s ability to maintain the playground area in compliance with all the standards that apply to public playgrounds.

This information is equally important to the playground owner/operator and designer prior to making a purchasing decision. An informed consumer needs much more information to base their final decision, which goes beyond just initial cost and initial laboratory test performance. These facilities are expected by our ASTM Standards to meet minimum performance requirements throughout the life of the playground. The owner/operator needs much more than just the critical height performance of the surface system. The surface system manufacturer/installer must not only provide the initial cost for the surface system, but they should also provide all requirements and detailed instructions for proper installation and maintenance of the system throughout the reasonable projected life of the playground. Beyond field performance and laboratory compliance testing, some reasonable warranty of compliance to performance standards should also be considered in purchasing decisions. The latter may need to be addressed by the consumer at the time of purchase as a condition of their agency purchasing contract compliance.

ASTM F1292 Standard to state in 4.4.2,

“When an installed playground surface is tested in accordance with this section, if the impact test scores at any tested location in the use zone of a play structure do not meet the performance criterion, bring the surface into compliance with the requirements of this specification or the play structure shall not be permitted to be used until the playground surface complies.”

If it is important for this statement to be a part of the F1292 Standard, then both the ASTM F1487 and F1292 Standards should require the manufacturer and/or designer to provide the who, how, what, and where requirements for equipment and surfacing compliance within this standard.

The information necessary to maintain compliance with these Standards should include everything related to maintaining performance including, but not limited to installation requirements; maintenance procedures and special materials or tools required; inspection frequency; routine and foreseeable maintenance requirements; and repairs required to keep the system in compliance with ASTM F1487 and the various impact-attenuating surfacing standards as referenced and implied below.

The rationale for supporting these additional requirements comes from the following;

ASTM F1292-09

INTRODUCTION

Surveys by the United States Consumer Product Safety Commission (CPSC) and others have shown that falls from playground equipment onto the underlying surface are a significant cause of injuries to children. Severe head injuries are the most frequently implicated cause of death in playground equipment-related falls. Use of appropriate impact-attenuating surfacing materials in the use zone of playground equipment can reduce the risk of fall-related injury. In particular, it is believed that the risk of life-threatening head injuries is reduced when appropriate surfacing materials are installed.

This specification specifies impact attenuation performance requirements for playground surfaces and surfacing materials and provides a means of determining impact attenuation performance using a test method that simulates the impact of a child’s head with the surface. The test method quantifies impact in terms of g-max and Head Injury Criterion (HIC) scores. G-max is the measure of the maximum acceleration (shock) produced by an impact. The Head Injury Criterion or HIC score is an empirical measure of impact severity based on published research describing the relationship between the magnitude and duration of impact accelerations and the risk of head trauma. The standard includes procedures allowing surfacing materials to be performance-rated before installation and for installed surfacing materials to be tested for conformance with the specification.

The purpose of this specification is to reduce the frequency and severity of fall-related head injuries to children by establishing a uniform and reliable means of comparing and specifying the impact attenuation of playground surfaces. Its use will give designers, manufacturers, installers, prospective purchasers, owners, and operators of playgrounds a means of objectively assessing the performance of surfacing materials under and around playground equipment and hence of evaluating the associated injury risk.

The scope of ASTM F1292 establishes minimum performance requirements for the impact attenuation of playground surfacing materials installed within the use zone of playground equipment. The standard is specific to surfacing used in conjunction with playground equipment. It is referenced in other ASTM Standards such as F1148, F1918, F1951, F2075, F2479 and ASTM F2223.

This Standard establishes an impact attenuation performance criterion for playground surfacing materials. This information is expressed as a critical fall height under both laboratory and in the field conditions.

The critical fall height of a playground surfacing material determined under laboratory conditions does not account for important factors that have the potential to influence the actual performance of installed surfacing materials. There are many variables known to affect surfacing material performance including but not limited to the natural aging process, excessive or lack of moisture, maintenance requirements, many environmental factors, compaction, loss of thickness, shrinkage, and the list goes on.

The impact attenuation specification and test methods established in this Standard are specific to the risk of head injury. The Standard states there is only limited evidence that conformance with the requirements of the standard reduces the risk of other kinds of serious injury (for example, long bone fractures).

This specification relates only to the impact attenuation properties of playground surfacing materials and does not address other factors that contribute to fall-related injuries. Many of these play equipment factors are addressed in the ASTM F1487 standard for performance requirements of public play equipment. Both ASTM F1292 and F1487 Standards state that conformance with the requirements of this specification will reduce the risk of serious injury and death from falls, adherence to this specification will not prevent all injuries and deaths.

The Standard also states it, “does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.”

When an installed playground surface is tested in accordance with this Standard and the impact test scores at any tested location in the use zone of a play structure do not meet the performance criterion the owner/operator of the playground shall bring the surface into compliance with the requirements of this Standard or the owner’s purchasing specifications whichever is more stringent or the play structure shall be taken out of service until the impact attenuating playground surface is brought into compliance. It should be noted there is nothing to restrict the owner or specifier of the purchasing and installation requirements to specify additional impact attenuation performance requirements, providing that such additional performance requirements are more stringent than the minimum performance requirements of this Standard.

ASTM F1487-11 Standard

Section 9. Playground Layout states, “There shall be a use zone for each play structure which shall consist of obstacle-free surfacing that conforms to Specification F1292appropriate for the fall height of the equipment.

The dimensions and configuration of the use zone shall be dependent upon the type of play equipment, as specified in Section 9. Use zones of certain types of equipment may overlap unless otherwise specified.”

Section 10 also stated public playgrounds shall comply with the DOJ 2010 Standard for Accessible Designwhere applicable.

Section 13 Maintenance requires the designer or manufacturer of each play structure provide to the owner/operator clear and concise inspection, maintenance, and repair instructions, including, but not limited to, what, when, and how to inspect, maintain, and repair their equipment. That being said it puts the responsibility of compliance on the owner/operator. The owner/operator is required to maintain the protective surfacing within the use zone of each play structure in accordance with Specification F1292appropriate for the fall height of each structure and the ASTM Standard F1951where applicable. This surface within the use zones of each play structure shall also be maintained free from extraneous materials that could cause injury, infection, or disease. And finally, the owner/operator shall establish and maintain detailed installation, inspection, maintenance, and repair records for each public-use playground equipment area.

All this being said, how does the owner/operator prove their surface is currently in compliance with these recommendations?

2010 CPSC Handbook

Section 2.4 Surfacing on page 8 states, “The surfacing under and around playground equipment is one of the most important factors in reducing the likelihood of life-threatening head injuries. A fall onto a shock absorbing surface is less likely to cause a serious head injury than a fall onto a hard surface. However, some injuries from falls, including broken limbs, may occur no matter what playground surfacing material is used.

The most widely used test method for evaluating the shock absorbing properties of a playground surfacing material is to drop an instrumented metal headform onto a sample of the material and record the acceleration/time pulse during the impact. Field and laboratory test methods are described in ASTM F1292 Standard Specification for Impact Attenuation of Surface Systems Under and Around Playground Equipment.

Testing using the methods described in ASTM F1292 will provide a “critical height” rating of the surface. This height can be considered as an approximation of the fall height below which a life-threatening head injury would not be expected to occur. Manufacturers and installers of playground protective surfacing should provide the critical height rating of their materials.”

So where should we go from here?

I think it is unrealistic to think that today’s standards related to performance of protective surface playground systems is adequate to address all the compliance issues the owner/operator faces in their challenge to select, install, inspect, maintain, and repair their playground surface systems within the performance parameters set forth in ASTM F1292, F1487, and the DOJ 2010 Standard for Accessible Design.

Questions

How do the current standards provide objective information to select the appropriate surface system for every situation when the primary piece of information the owner/operator has to base their purchasing decision on is the laboratory test report for a DRY SAMPLE at 3 specified temperatures? How was that test sample installed at the lab in the specified 18 inch square test box? Is this same installation process for the 18 inch test box specifically and strictly followed in all field installations regardless of how large? Are unitary and loose-fill test samples exactly the same as the surface system materials purchased and installed in each and every playground year in and year out? They would need to be for at least the five years if the IPEMA Surface System Certification is valid. Then when the surface system is up for re-certification, all following installations would need to be consistent with the new test sample and test results of both the laboratory and in the field.

Suggestions

I would like to make some suggestions for additions to the current ASTM F1487 and/or F1292 Standards to help the owner/operator assure compliance to these standard performance requirements at least on the first day the playground opens to the public.

The following should be considered for addition to Section 13 Maintenance of ASTM F1487-11:

- The playground equipment manufacturer and/or designer shall provide written verification of compliance to ASTM F1487 in the field after installation.

- The protective surface system manufacturer shall provide written verification of compliance to ASTM F1292 and ASTM F1951 in the field after installation.

- The protective surface system manufacturer shall provide detailed written inspection, maintenance, and repair instructions to the owner of the system.

Many owner/operators already require these things as part of their purchasing documents, but many agencies are not as attuned to these best practices. I do not believe any of these things will add substantial cost to the surface system. By requiring these things be done prior to opening a public playground may be the only time the owner/operator, manufacturer, and the equipment and surfacing installers can say the project and their products were installed correctly and in compliance with both F1487 and F1292 and the 2010 Standard for Accessible Design.

I would also suggest owner/operators consider field compliance verification with the ASTM F1951 Standard to address accessible route compliance within the use zones. Before everyone overreacts to this recommendation, please read on and then give this some further consideration.

I think this is possible even without an ASTM field test method for easy post installation verification on site. Here is how it can be accomplished. First, the surfacing system and equipment must be installed according to the manufacturer’s stated installation process. This would be confirmed in writing by both the surface system and play equipment providers by the manufacturer, or their agent, prior to final acceptance. The Access Board has stated they would consider performance test comparisons of the playground accessible route and use zones between the laboratory ASTM F1951-04 test results and field test value results utilizing the Rotational Penetrometer Test Method after the surface system final installation process was certified in writing. The results of the laboratory ASTM F1951 test and that of the Rotational Penetrometer in the field would provide a benchmark comparison for the ongoing maintenance of performance requirements for accessibility regardless the type of surface system in question. The current estimate to conduct a laboratory F1951 test in the field would more than likely exceed $10,000 and the cost of the Rotational Penetrometer and a field test would be much more manageable. Does this seem reasonable?

Compliance to the equipment use zone clearances and the impact attenuation requirements within this area are a big part of injury prevention, but does nothing to protect the owner/operator when an ADA complaint is filed against them. As I stated earlier in this column, the responsibility for compliance and removing the playground from use until deficiencies can be rectified has been placed squarely on the shoulders of the owner/operator.

Unless the owner/operator has written proof of compliance from day one of the playground, they have no way of protecting themselves from a legal action brought against them, once the plaintiff can prove the surface system is not compliant with the minimum standard requirements. Buyer Beware.

Supporting Rationale for these recommendations:

- The current ASTM F1487-11 Standard states in Section 13.2.1 “the owner/operator shall maintain the protective surfacing within the use zone of each play structure in accordance with Specification F1292 appropriate for the fall height of each structure and Specification F1951 where applicable.”

- ASTM F1487-11 Standard Section 13.2.2 states “the owner/operator shall maintain the protective surfacing within the use zone of each play structure free from extraneous materials that could cause injury, infection, or disease.”

- ASTM F1487-11 Standard Section 13.3 states “the owner/operator shall establish and maintain detailed installation, inspection, maintenance, and repair records for each public-use playground equipment area.”

- ASTM F1292-09 Standard Section 4.4 Performance of Installed Playground Surfaces states in 4.4.1 “When an installed playground surface is tested in accordance with the requirements of Sections 16-19 at the reference drop height, the surface performance parameters at every tested location in the use zone shall meet the performance criteria of this specification. The reference drop height shall be the greater of (1) the height specified by the owner/operator prior to purchase, (2) the critical fall height specified when the playground surface was installed, (3) the equipment fall height, or (4) the critical height of the surface at the time of installation.”

- ASTM F1292-09 Standard Section 4.4.2 states “When an installed playground surface is tested in accordance with this section, if the impact test scores at any tested location in the use zone of a play structure do not meet the performance criterion, bring the surface into compliance with the requirements of this specification or the play structure shall not be permitted to be used until the playground surface complies.”

- ASTM F1292-09 Standard Section 4.4.3 More Stringent Specifications—The specifier is permitted to specify additional impact attenuation performance requirements, providing that such additional performance requirements are more stringent than the performance requirements of this specification.

- The 2010 CPSC Handbook Section 2.4 states, “Manufacturers and installers of playground protective surfacing should provide the critical height rating of their materials.”

- The 2010 CPSC Handbook Section 4.1 Maintenance Inspections states, “A comprehensive maintenance program should be developed for each playground. All playground areas and equipment should be inspected for excessive wear, deterioration, and any potential hazards, such as those shown in Table 3 (Specifically Problems with surfacing i.e. displaced loose-fill surfacing, holes, flakes, and/or buckling of unitary surfacing). One possible procedure is the use of checklists. Some manufacturers supply checklists for general or detailed inspections with their maintenance instructions. These can be used to ensure that inspections are in compliance with the manufacturerssurfacing specifications.”

Conclusion

The only way these conditions can be verified by the owner/operator after initial installation is to have the

- surface system performance verified to ASTM F1292 and ASTM F1951 after installation

- surfacing manufacturer, supplier, or installer provide all information necessary

to assist the owner/operator comply with the 2010 CPSC Handbook, ASTM F1487-11 Section 13.2.1 through 13.2.3, ASTM F1292-09 Section 4.4.1 and 4.4.2, and DOJ 2010 ADA Standard on Accessible Design.