Designing and building a playground is always a unique experience. Each area has individual character that is defined by any number of man-made or natural elements. Every playground should be approached with an interest in community involvement. Bringing local children and other individuals into the process may be the difference between a playground that gets utilized and one that is ignored.

Prior planning prevents poor playgrounds, a twist on a familiar quote, yet just as true. Begin by asking yourself who, what, where, why and how questions about your playground. Your best answers to these questions will eventually address the key issues: location, funding, needs of the users, product choices, installation, maintenance, and safety. You will need to know about local building codes and construction permits. You will need to ensure your playground is handicap accessible. There are many questions to be asked and answered. A systematic approach that utilizes your resources will set you on your way.

Forming a committee will lead to a greater chance of a successful playground project. Involving your local businesses will give you a feel for community support and possible financial assistance toward your goals. You will also build a source of people power that will help to get the work done. Be sure to bring children into the equation, as adults tend to view “fun and exciting” in a different light than the local youngsters.

The key issues need to be addressed before any child can laugh and play at your park. Developing an outline for designing and building a playground may look something like this:

- Form a committee

- Site analysis and acquisition

- Designers and architects

- Equipment evaluation

- Surfacing evaluation

- Purchasing the materials

- Construction and installation

- Maintenance

Site analysis could be the most important aspect of this project. Location is critical to the safety and accessibility of your playground. Be sure there are no road or vehicle hazards for children accessing the park. Look out for areas that have deep standing water. Is the parking close enough to allow parents access? Is there adequate access for emergency vehicles and maintenance crews?

You must also consider sidewalks and paths to the area as well as all ADA accessibility requirements. Are there poisonous animals or plants, thorny or dangerous trees or bushes? Is there natural shade, or do you need to install some? How will you provide restrooms, drinking water and security? Site analysis must also address soil stability, drainage, and topography (playgrounds usually can’t be built on a hillside without a special design.)

Be sure to find the location of the utilities, overhead and underground. Check for gas pipes and water lines. These are the types of things a great site analysis provides. A proper site analysis will help you eliminate future problems and also help with the design of your play area.

Utilizing a designer or architect is a good way to make sure you have a good plan to implement. Many companies provide design services by people trained in American Standards for Testing Materials (ASTM) and ADA requirements. These companies can help with most projects that involve the equipment and surfacing. They can design independent equipment that best utilizes your area. They can design unique structures that accommodate themes and aesthetics. They may offer computer systems that will give you 3-D drawings so you can see just how your playground will look. Additionally, you may need to work with an architect to address things such as drainage, landscaping, sidewalks, curbs or local construction issues. Many landscape architects include playground design as part of the scope of their work.

Equipment evaluation is the most fun yet often the most frustrating task in getting to the end of your playground project. There are many types of playgrounds; wood, metal, plastic, recycled, manufactured, homemade, and on and on. Today we have traditional playground equipment such as swings and climbers or we can get an elaborate “play structure”—a combination of many elements hooked together. For as many types of playgrounds as there are, there are as many manufacturers of playground equipment. The International Playground Equipment Manufacturers Association (IPEMA) lists over 100 members. Most of these manufacturers provide design and assessment programs to help you choose the equipment that best suits your needs. When working with a manufacturer or designer of playgrounds make sure to check their credentials and verify they are conforming to the U.S. Consumer Protection agency’s handbook for public playground safety. Some even offer a third-party certification to compliance with ASTM Standards. Check manufacturer’s warranties, have them show you samples and give you references of recent work. Contact their customers who have used their products over an extended period of time.

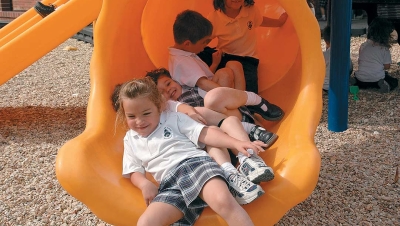

Once you have picked safe and durable equipment, you need to pick the style and components of your playground. Your choice must address the number of users, the age and the development skills of the children. It should also be appropriate for the climate in your area. You may choose to build your playground around a theme. Many companies build forts, boats, mountains or specialized themes. After you have identified all of these fun challenges and chosen wisely, you can settle on colors and accent details.

Seventy percent of playground injuries are related to falls. Many of these are falls to the surface. For safety’s sake, surfacing is a critical part of your playground design. Wood and rubber products have replaced traditional sand and gravel. Surfacing needs to address three important issues: “softness,” stability and durability. “Softness” is technically called impact attenuation and refers to head injury criteria. Surfacing must provide some form of deceleration to a fall. Second, surfacing is required to be “stable” and therefore accessible by those with physical handicaps and limited to wheelchairs or crutches. All public structures must be ADA compliant. Third, a surface must be durable. Loose fill surfaces may require a beefy system under high traffic areas. Unitary surfaces also require maintenance and repair in high traffic areas. Your surfacing may require a border for containment of loose-fill material or for securing a unitary material. Your research on your playground site and user needs should direct your final decision in this important area.

When you have reached the point of purchasing the equipment you are on the downhill side of your playground project. You may purchase with a “request for proposal” or “design-build.” This type of purchasing allows you to pick the equipment that best suits your needs.

Many cities and schools purchase in a competitive bid system ensuring they receive the best price on a playground design. However, you purchase, be sure to check the credentials of the architects, designers, manufacturers, installers or others involved in your project. The National Playground Safety Institute (NPSI) provides a playground safety inspector certification program that many manufacturers, installers, and playground owners have completed. It would be prudent for anyone planning a playground to include a certified playground inspector in his or her process.

Your site has been analyzed. The equipment and surfacing have been researched and purchased. You are now ready to build your playground. It can be “community built” or you can hire someone to build it for you. Ensure whoever builds it knows and follows construction safety rules. Be sure the pending playground area is secured so anxious children do not expose themselves to construction hazards. Be aware of equipment and surfacing that will need to be unloaded at the job site. Check that the utilities have been marked and that you have the tools you need to do the job well.

All manufacturers provide installation instructions for their equipment. Understanding and using these manuals is crucial to the success of the construction project and the safety of the users of your new playground. If you are doing a “community built” playground, make sure you have a qualified person to follow U.S. Consumer Product Safety Commission (CPSC) guidelines and manufacturer manuals. The National Playground Contractors Association (NPCA) lists over 200 members.

The kids are playing, the bills are paid, the community is smiling, and your playground project is complete at last! Hold on, a playground project is never complete.

A playground area requires a systematic maintenance program. Even a tough playground needs to be checked for glass, litter, insects, vandalism, wear and continued safety. Do not neglect this part of your project. Many playground accidents are a direct result of lack of maintenance.

Designing and building a playground is always a unique experience. Your playground blends into your community. It compliments the neighborhood. It provides a place children can call their own. As the details of this important community project fade in your memory, many significant memories are being made on the new playground. The benefits of a well-planned and executed playground project are long-lasting and far-reaching. The squeals of delight, broad smiles, and rush of excitement that fill the once vacant spot are your reward for thorough planning efforts.

Add new comment