Soft Contained Playgrounds are Growing Up

Soft Contained Play Equipment (SCPE) is no longer the baby of the playground family. The Standard for this equipment was published by the American Society of Testing and Materials in 1999. It is referred to as ASTM F 1918-99 Standard on "Safety Performance Specification For Soft Contained Play Equipment".

The standard is the work of the ASTM F15.36 committee. It has been close to seven years since the committee was formed. As with all the playground committees, the work is never done. At the March meeting of 2001, a revised standard was voted on and should be pubIished around June. The purpose of having a safety performance

specification is to provide safer play experiences for children and to reduce the potential for life-threatening and debilitating injuries. The user group is from the 5th percentile 2-year-old to the 95th percentile 12-year-old, the same age range as the Public Playground Equipment Standard, ASTM F 1487.

Walt Henderson chairs the Soft Contained Play Equipment committee, with Marylou Iverson Co-chairperson and Dr. Francis Wallach as Secretary. Members of the committee are manufacturers of SCPE, public playground equipment, surfacing companies, consultants, and others interested in children's play.

FOOD AND FUN

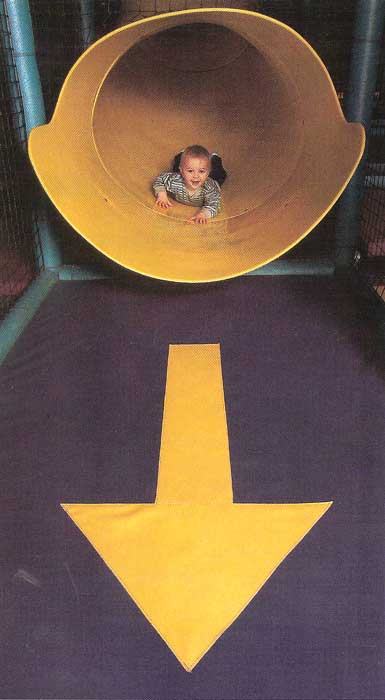

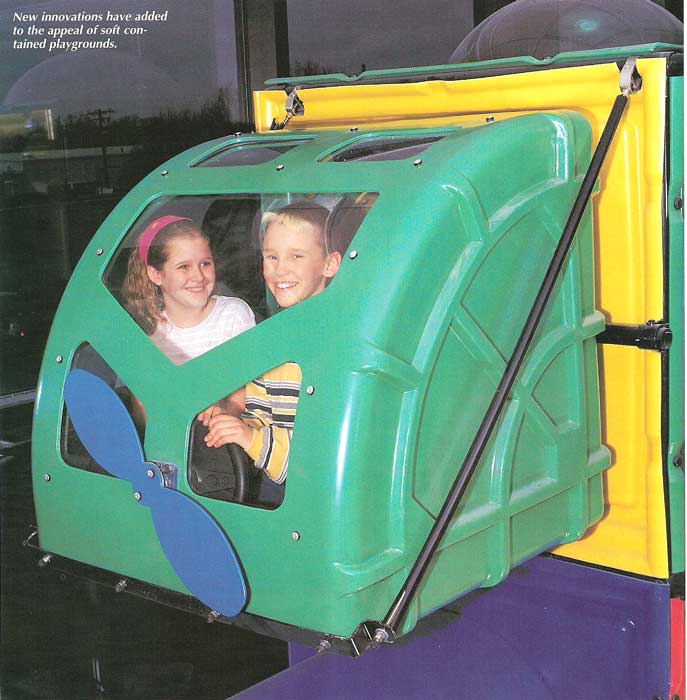

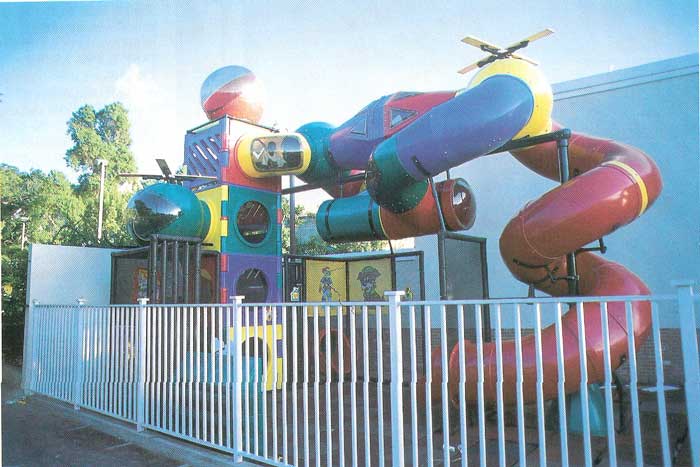

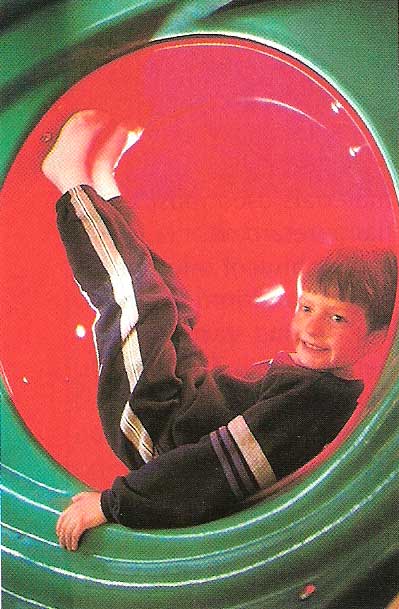

Fast food restaurants are the biggest user group of SCPE. It has been proven that the play space, when well maintained, will increase sales. The family fun center concept has expanded to the public sector at municipal park and recreation facilities. Some departments have their play space as a family play area, along with the gym and swimming pool or in the daycare. These play spaces are filled with adventure for children under 12 as they wind their way through the maze of tunnels, climbers, moving-jiggling and twisting components, plus all those slides. Even the under 2's have a safe place to play. As with the public playgrounds, it is recommended the soft contained play equipment be divided into separate areas for children 2 to 5 and 5 to 12 years of age.

Since we started working on the standard, I have inspected SCPE play spaces around the country. This past year I inspected some family fun centers that have been in existence for about eight years. I was impressed at how well they've held up under a good maintenance program. I observed many details that were out of compliance with the standard. In these areas, accidents have occurred. It was reassuring that the work we are doing in the F 15.36 committee really does make a difference. Gambling casinos in various parts of the country offer SCPE play spaces as a healthy, fun, alternative activity while the parents are gambling. Most of these centers have the play space as the focus of play but have added computer programs, games and interactive play events for the older children. Playspaces in fast food restaurants vary in sizes depending on what the store wants to accomplish through play. Some only want kids there for 20 minutes during food preparation, while others want kids to stay several hours.

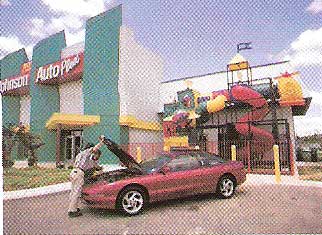

SCPE play spaces are also showing up in grocery stores. The cost is minimal compared to the cost of a claim where a child has fallen out of a grocery cart. Some stores are free or free for the first hour. SCPE playspaces function well at video stores, auto dealerships, auto rental agencies, and airports. They work in many environments where having a safe entertainment for the children frees the parents to focus on business. Hospitals have discovered SCPE play spaces not only keep children occupied, but are a great therapy tool for children and adults.

Older play spaces and SCPE units that have not had regular maintenance will have hazards. They will no longer be in compliance with the Standard. The more serious hazards are pinch points, crush, sheer, clothing entanglement and head entrapment. The standard has helped in getting SCPE units installed without hazards, but they will surface over time if there is not a good maintenance and repair program. As hazards surface so does the potential for an accident and the potential for liability

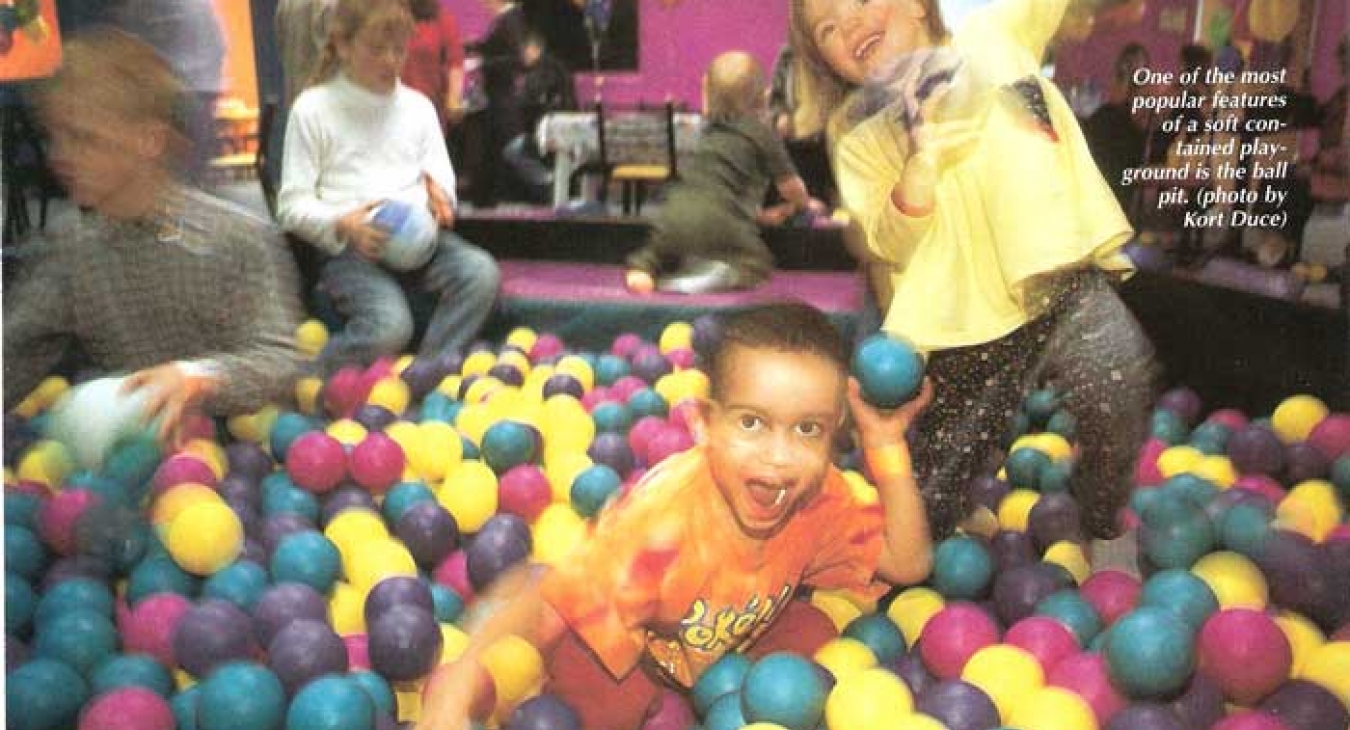

claims. Several years ago, Consumer Product Safety recalled all slides that exited into ball pools. This decision came from an investigation into the death of a child who died in a ball pool. There was potential and possibility of the accident happening again, so manufacturers were asked to remove slides from existing ball pools. CPSC has also addressed ropes that are not secured at both ends. Ropes must be fastened at both ends and not be able to make a 5-inch interior loop. Health departments have been very concerned with ball pools in SCPE units located in fast food restaurants. If the balls are not cleaned regularly and often, they can breed many forms of bacteria harmful to children.

This standard is the benchmark for design, installation, and maintenance, and that criteria are a part of this standard. Providing this standard is followed, it will lessen liability for owner/operators, contractors, installers and maintenance companies. More important than that, it will provide safe play spaces for children.

SETTING THE STANDARD

Let's look at the F1918 Standard starting with the definition of SCPE: play structure made up of one or more components where the user enters a fully enclosed play environment that utilizes pliable materials.

The Materials Section states that SCPE shall be manufactured and constructed only of materials that have demonstrated durability. The materials shall not utilize known hazardous materials that could be ingested, inhaled, or absorbed through body surfaces as a result of contact with the equipment. All fasteners and threaded features shall not be able to be removed without tools.

Performance requirements are basically the same as for public playground equipment. Because much of the material in SCPE is soft, testing using the head entrapment is important. I saw a hole in netting recently that had occurred because of lack of maintenance and a child had fallen through. This child was not hurt. Had it not been corrected, the next child might not be so lucky.

To inspect bounded, non-rigid openings, the torso probe is inserted to a depth of four inches and applied a force of 50 pounds. If the torso will go through the opening, then the head probe is inserted and if it won't go through, then it is head entrapment. When children crawl through these play spaces, their faces are close to surfaces most of the time, so it is important that there are no protrusions to injure the head area or entanglements to entangle clothing around a child's neck. The testing procedures are given in the standard. The play spaces must continually be checked for pinch point, sharp edges and projections.

Fire safety requirements are necessary for indoor SCPE play spaces. If a fire were to occur in the play space it would most likely be detected first by a smoke detector. Emergency lighting and standard exit signage are needed to help users orient themselves in finding the building exit once they have exited the equipment. The type of materials used must be flame retardant. A lot of research went into this section and into evaluating existing standards for flammability. The information in this section references NFPA Life Safety Code and other codes that have been tested on similar materials to what is used in SCPE play spaces.

There is a section in the Standard on evacuation. There needs to be an evacuation route that a monitor will be able to reach any point within the SCPE in less than 60 seconds. AlI dead ends much have a cross section of at least 39 inches and should not be more than 120 inches long. The intent is to allow an aduIt to reach a chiId, turn around and exit the play space.

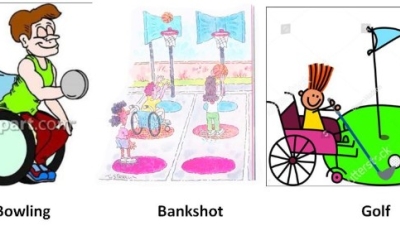

There is a section on accessibility. The Architectural and Transportation Barriers Compliance Board, Americans with Disabilities Act, Accessibility Guidelines for Building and Facilities; Play areas; went into effect on November 17, 2000. These Federal Guidelines address soft contained play structures by requiring an accessible route to serve entry points of the SCPE play spaces. Where there are three or fewer entry points, at least one must be located on an accessible route. Where there are four or more entry points, there must be at least two entry points located on an accessible route. There must be an accessible route of travel to the SCPE. Accessible routes must comply with ADAAG. SCPE play spaces are wonderful to play opportunities for children with all types of disabilities. Some get tremendous enjoyment by just sitting in the ball pool, while others can crawl through the playground and delight in being able to make choices of which way to go. The Standard also addresses accessible play opportunities located outside of the SCPE play space and within reach range of wheelchair users. When SCPE units are retrofitted, they need to meet the Federal Guidelines. The guidelines can be found on the web at www.accessboard.gov or call 1-800 USA-ABLE for a copy.

COMING AND GOING

A primary concern with ball pools is the designated play surfaces at the entrance above the level of the balIs where children may be encouraged to jump and land on other users submerged in the balls.

The use zones for entrances and exits shall have resilient surfacing for a width of 60 inches and be clear of obstacles.

Straight slide exit's use zones must meet the requirements of ASTM F-1487, but the enclosed spiral slide's use zone has different requirements. Impact attenuated surfacing is required in the use zones and must meet ASTM F 1292. The fall heights are usually not more than one to three feet. If mats are being used, there must be adequate ramping to prevent tripping and to comply with accessibility requirements.

The structural integrity section has expanded from ASTM F 1487-95, using information relevant to SCPE. With the pliable protective barriers, the safety factor is in the test loading, which is directed at the 95th percentile 12-year-old users pushing against or climbing the netting. It also addresses no-climb netting.

The maintenance section describes what the manufacturer must supply to the original owner/operator. It includes maintenance and hygiene instructions for cleaning and sanitizing the equipment. Adhering to these recommendations is critical for the life of the SCPE playground. There are more preventive maintenance recommendations and frequency procedures for inspections and maintenance. In the manufacturer's operation instructions, a description of the intended use is given along with the weight or number of persons the unit can accommodate and recommendations for use relating to environmental conditions on the outdoor units.

I am aware of pending legislation for maintenance and inspections of soft contained equipment play spaces in Tennessee, and in New Jersey, the law goes into effect July 1, 2001. There are state regulations in Pennsylvania.

I surveyed a lot of SCPE that has been in use for up to ten years. With units that have had regular maintenance, repair, and a cleaning program, these units are in as good of shape as when they were installed, except many were out of compliance. Because these units are modular, certain play components can be changed periodically, keeping the play attractive to the users. When units are not maintained or inspected on a regular basis, accidents do occur. Vandalism and wear take its toll, and if these hazards are not corrected, the potential for accidents is present. The potential for serious accidents in SCPE play spaces is less than on public playground equipment. Injury statistics for all playground accidents are reported at 260,000 through the National Injury Surveillance System. There is not a breakdown of how many of these took place in SCPE play spaces.

TAKE A LOOK

The best place to see soft contained play equipment is at the trade shows. The International Association of Amusements and Attractions will be held in Orlando, Fla., Nov. 12-16. The Fun Expo will be held in Las Vegas, Nev., October 4-6. If you are considering purchasing soft contained play equipment or are a contractor involved in installing and maintenance, I suggest you purchase a copy of the ASTM F 1918 from American Society for Testing and Materials, 1 00 Barr Harbor Drive, West Conshohocken, PA 19428-2959, or telephone (61 0) 832-9706. The cost of the Standard is $28.00. If you are a member of ASTM, the Standard can be accessed through the web.

Add new comment