There are many ways to think about playground surfacing. Is it accessible and safe, does it drain, what does it cost? How does it affect those who use the playground? Can we imagine what the future holds for playground design and surfacing needs? How did our current surfacing solutions evolve?

Sand

The changes to landing surfaces over the past several decades have drastically transformed what can be expected from a playground. By the ᾽70s most playgrounds had replaced dirt or asphalt with sand. The logic was that injuries from falls were reduced and the sand was a great play material. The first big change was brought about by the published safety guidelines by the U.S. Consumer Product Safety Commission (CPSC) and later by standards developed by the ASTM International (ASTM).

The CPSC correctly pointed out that some 80% of injuries, and as many as 95% of serious injuries, were fall-related. This appeared at the time like an easy fix, but it turned out to be full of extremely difficult issues, and the solutions had some unfortunate unintended consequences. For example, CPSC gave recommendations for surfacing that showed that sand was not sufficiently fall attenuating. This guidance resulted in the wholesale removal of sand from playgrounds but was based on faulty data. First, the experimental apparatus used a sand containment box that was too small and the edges prevented the sand from displacing and lowering the test scores. Secondly, the tests did not consider the shape of the sand particle. Much later tests using round particle sand found that this material is an adequate landing surface.

Rubber and wood chips

With sand removed as an option, designers were left with rubber and wood chips. In this early phase there were two main options for rubber surfacing: mats and poured-in-place (PIP). Neither of these options was particularly appealing. Leaving aside the issue of cost, the interlocking mats tended to have problems with surface regularity and with corners and edges curling up. The early PIP had problems with installation quality. Recognizing these issues, the ASTM developed performance and testing standards to ensure consistent functioning.

The upshot of these early experiences was that wood chips became the surfacing of choice. Problem solved. Well, not so fast. Turns out that wood chips are not accessible. Now what to do? The solution was Engineered Wood Fiber (EWF) largely developed by Robert Heath. His Fibar product solved the access issue by fracturing the wood into long fibers, which then knit together making a firm and stable surface. Problem solved? Once again not quite solved as the early material was extremely sharp and there were a lot of complaints about splinters.

After a decade and more of real life experience and a lot of work on the part of the industry, these early teething problems have largely been solved. But that is not the point by recounting this short history. In hindsight, was the standards process the best that could be done? Was it a smart thing to require new landing surfacing on all playgrounds across the nation without some form of real world testing?

What about efficacy? To this day there is no experimental or statistical evidence that adding EWF or PIP actually reduces injuries. It was known, or should have been known, that human behavior is complex, especially when it comes to play and playgrounds. There were, at the time of these changes, risk management studies that tended to support the notion that when things are made safer, children often tend to behave badly because they have a natural tendency to think that nothing will go wrong for them; that safety measures are for the other kid.

Have surfacing standards reduced injuries?

It would not have been difficult to set up a test, but arrogant thinking that designers know best led to this glorious social experiment at tremendous cost. What could go wrong? What has gone wrong is that the predicted reduction in accidents has not materialized. Why? It actually is not known. Some think that rubber surfacing, while perhaps good at preventing head injuries, actually increases long bone injuries. Others feel that kids will always play up to the point of pain, and soft surfaces just encourage high-risk behavior. These folks cite the low incidence of injury on skateboard parks in which kids often fall as evidence of this human tendency.

Undaunted by the failure of their expensive experiment and the total lack of an understanding of the human factors involved with playground injuries, the ASTM surfacing committee recently tried to make the surfacing standard even more stringent and require even more performance testing. Thankfully, cooler heads prevailed, but the issue may rise again.

Yes, playgrounds are safer despite the lack of hard evidence. Yes, good surfacing options are available nowadays. But would designers do the same things the same way again? Probably not. Why then should they continue down the same path? Perhaps there can be a different approach to playground design and safety, one without unintended consequences, one more suited to the times.

Do million dollar playgrounds make sense?

A recent article in the Washington Post bore the shocking headline: The cost of play tops $1 million for some local playgrounds. It is not a secret that playground design and construction costs have been steadily escalating over the past couple of decades, driven primarily by safety and access requirements.

How did simple play become a million dollar investment?

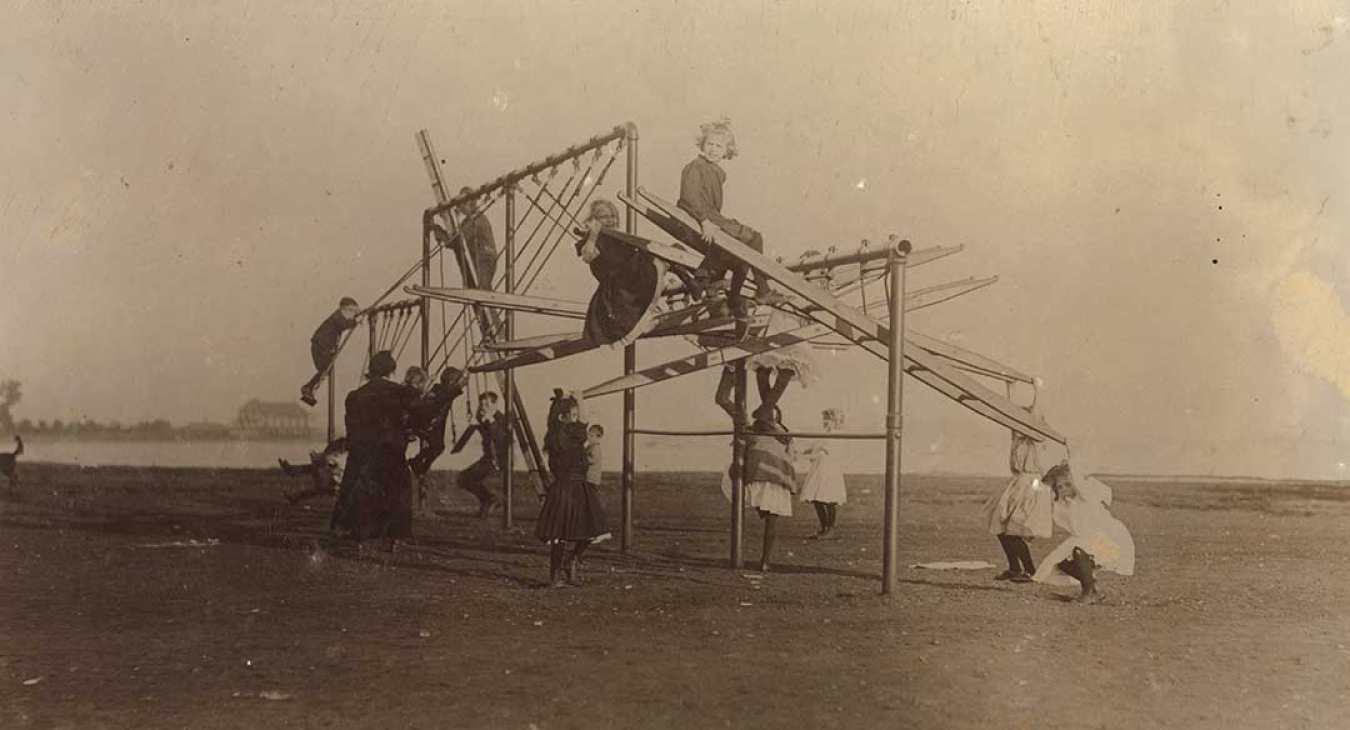

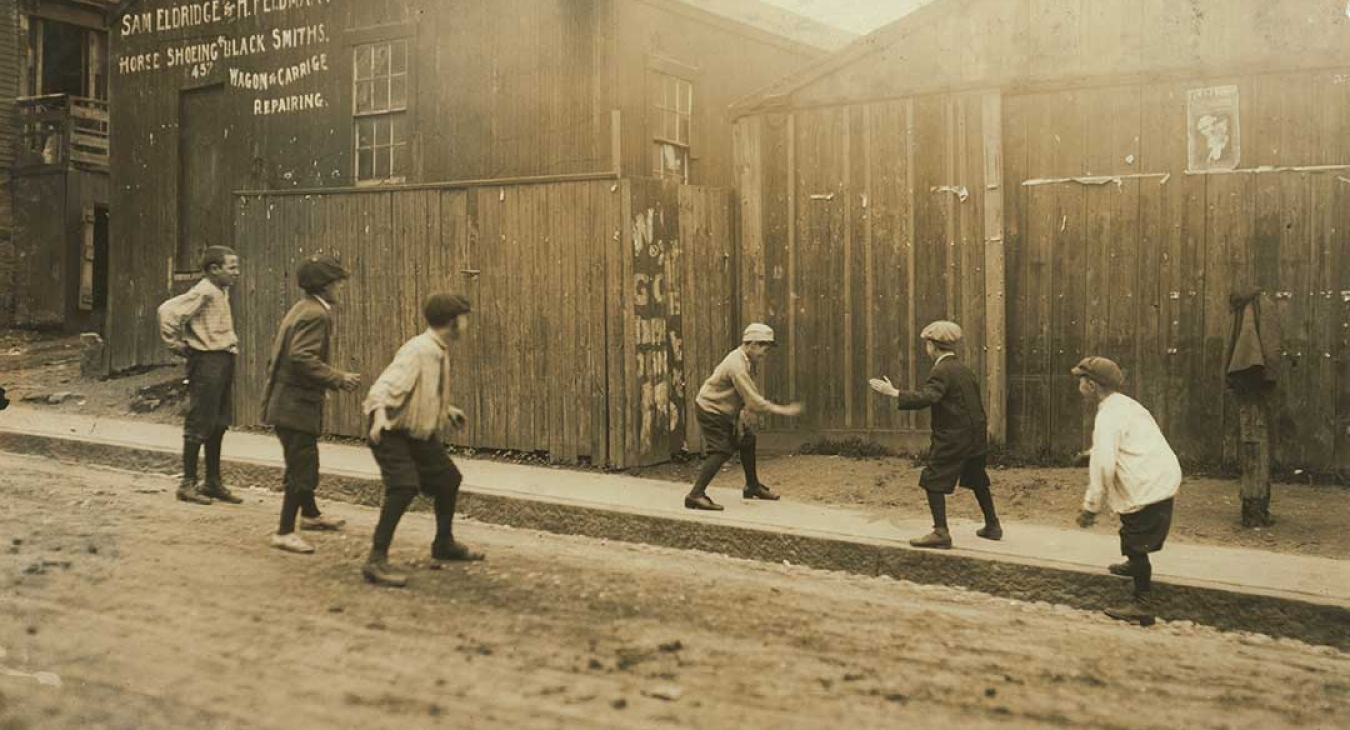

In the early days of the industrial revolution both parents often worked. If kids were too young to work in the factories, they played in the streets, which interrupted traffic. The solution was to create a place where children could exercise in a healthy way. The literature from those early years makes it clear one of the prime motives behind the creation of the first playgrounds was to control the “street urchins” and actually to put a stop to play.

With the best intentions, designers think they are doing a “good thing” when they dedicate the space, money, and time to creating playgrounds, and to some extent, this is true. But all too often playground design is all from Column A with very little from Column B. (See above.)

There is a huge difference between Playgrounds and Play!

A: Playgrounds |

B: Play |

|---|---|

|

Play on |

Play with |

|

Maintenance free |

Messy |

|

Fixed |

Flow |

|

Entertaining |

Engaging |

|

Safe |

Challenging |

|

Expensive |

Free |

|

Created by adults |

Created by players |

|

Manufactured |

Emergent |

|

Age appropriate |

Inappropriate |

What is the greatest design criterion for most playgrounds?

Ask yourself, what is the single greatest design criterion for playgrounds, the test that must be met above all else? Play value? Safety? Cost? None of the above. The first and foremost design benchmark for most playgrounds is “maintenance free.”

Nowhere is the issue of maintenance more prominent then when considering landing surfaces. As the million dollar playgrounds become more the norm, it is not surprising that so too does the installation of edge-to-edge PIP rubber surfacing. In other words, if cost is not a determining factor, then maintenance-free design rules the day.

Playgrounds can and should be spaces for living creatures, i.e. children. They can even be places that are primarily drawn from Column B. The difference is that instead of a million-dollar investment, such play-focused spaces can cost a fraction of that, but may also have the on-going expense for play leaders and frequent maintenance. As many good examples have demonstrated, such softer spaces do not have to look like funky adventure playgrounds, not that there is anything wrong with that. Adventure playgrounds represent an extreme example of a Column B playspace. But if playground owners are willing to make million-dollar investments, why not make playspaces that combine the best qualities from both points of view?

The photo below is from the Children’s Museum of Sonoma County. This water feature is just one of the many hands-on playspaces within the museum. While this example is likely to be both more expensive and more maintenance intensive than what many park departments can support, the experience gained in this installation and in similar children’s museums across the country will begin to develop a body of knowledge that can be transferred to public parks.

The environmental case

The predominate trend in city planning these days is to include climate change in the discussion. Whether you personally agree that climate change is real, the fact is that this trend will not go away, and the park and recreation professional would be well advised to align with this new direction.

The choice of surfacing materials is a case in point. On one hand, it’s great to be able to repurpose automobile tires and keep them out of the solid waste flow, at least for a decade or more. A short-term fix at best, it should not be thought that rubber playground surfaces are a solution to this pernicious solid waste.

Loose-fill rubber

A surfacing option not previously mentioned is loose-fill rubber nuggets. This is a strange beast. On one hand, when installed in sufficient depth, it has the best fall attenuating performance. On the other hand, it requires frequent re-leveling. There are also concerns about ingesting pieces and inhaling rubber dust as well as the potential fire hazard.

EWF is obviously a better environmental choice than rubber. There has been an on-going debate about using recycled lumber versus virgin timber. Recycling should be the best choice, provided that all contaminants such as nails, paint, and chemicals have been thoroughly removed. This is a labor-intensive task that increases the cost but reduces deforestation. There are EWF products that are actually using some of the millions of dead trees killed by the bark beetle infestations brought on by climate change. How ironic is that?

How will climate change affect the design of playgrounds?

In the not too distant future, the standard for housing and community design will change drastically. We will see an end to McMansions and the rise of Micro-homes. The indicators are already out there in the popularity of Tiny Houses and Eco-villages. We will see the end of the backyard swimming pool and an increase in community pools. As homes become smaller, people spend much more time in common spaces, and these will have leisure components that are likely to fall under the parks and recreation jurisdiction. These new “commons” will be more akin to European village spaces and a distinct change from most current public spaces.

What this discussion is intended to stimulate is to ask, if the budget for the typical destination playground is now close to a million dollars, does the way they are currently designed make sense? If it is true that common spaces will become increasingly important, then adequate budgets are certainly appropriate. But with significantly increased population density, does a playspace that is populated with metal and plastic furniture with wall-to-wall rubber make sense in human terms? As the public becomes increasing aware of the impact on the planet of the use of materials and energy, will the intensely manufactured playground paradigm of today match the sensibilities of tomorrow?

Can playgrounds be designed to last 100 years?

Also, consider that it is now common practice to either replace or significantly upgrade playgrounds every 20 years or less. This pattern of rapid obsolescence will change as well. Why? As the community comes to use their public spaces more intensely, they will also come to value them more and more. The future will be so full of rapid change that there will be resistance to uproot those places where the public has deep emotional bonds. That means designers should be designing play areas that will last a hundred years or more.

The term “sustainable” is overused, but it is the right term to use here. Future playspaces must be alive, able to self-repair, accepting of intense use, and be filled with fundamental and enduring pleasures. The relationship between the public and the common space will change from a consumer to that of a mentorship. The community will be directly involved, nurturing the space and giving it a sense of place.

The function of playgrounds is to provide a place where children come to grow, gain skills, find friends, and become confident in themselves and their community. As playgrounds serve multiple generations, they will increasingly become a point of shared interest within the community. They will become the heart of the community for everyone, not just a service for those families with young kids.

What will a playspace designed to last 100+ years look like? Perhaps designers should look around for spaces that have such longevity and learn from those. What an exciting challenge!

So replaced sand with Fibar EWF is no longer best practice?

Wow, I just learned so much from your article. What you say also fits with the science about children benefiting health-wise from more nature. More immediately, yesterday I found a sign at my little neighborhood park saying that the sand will be replaced next week with "safe fall" bark chip, on the grounds of superior safety. I couldn't find anything on google scholar to back up the safety claim, and in fact found various articles to the contrary (e.g. Andrew Howard, 2009). I was thinking the sign was deceitful but maybe outdated instead? Is there a clear best practice I can point to if I'm able to reach the architect in charge on Monday? My son loves the sand! Thank you!

playgrounds surfaces and safety

Having been a play practitioner ie adventure playground manager and play organiser for many decades in the UK I feel that a certain aspect of childs play and equipment seems to be totally ignored in this subject.Children need room to play both in area and within play equipment.I have noticed the common mistake by adult designers of playgrounds that there is insufficient thought given to how children actually play on these areas and too much given to the overall look of the playground.Children need plenty f space between items of play equipment to allow for fast flow and ability to stop and go from one piece of equipment to another I ve seen so many playgrounds here n USA where the structures are castle like with towers and do not allow the free flow movement of running kids etc.Often these are poorly used and though well maintained they do not offer sufficient play options for all ages of children often the structures are extremely hard and lacking in any form of springyness or fun structures packed too close together so making them unusable.

GFRC

Thanks for the comments. I'm not a big fan of GFRC as it only looks like natural material and has none of the intrinsic qualities. The real answer is "self-healing" environments which basically means organic but such natural settings have a hard time dealing with high use. Children's museums are leading the charge in developing such environments.

Playgrounds of the future

As a longtime admirer of Mr. Beckwith I find myself in total agreement with his assessment of safety surfacing as an ongoing issue - most of us older designers grew up in the days when there was no safety surfacing and I can't remember anyone sustaining a serious injury. Maybe we did play more with more regard for the dangers out there and took less risks. Either way, I don't see safety surfacing going away anytime soon and we have to live with the fact that it is an imperfect solution to a liability. Every manufacturer of safety surfacing materials has different specifications and the installations are for the most part, dependent on the installer's knowledge of chemistry and how PIP and tile respond to weather conditions.

With regards to playgrounds lasting 100 years ... I don't see that happening unless the playgrounds are made out of materials like GFRC and covered completely by shade systems. With climate destabilization and the warming trend, most of the playgrounds I design for the northeast region are virtually useless during the hot summer months (when they are needed most) because they are just too hot to play on unless they are covered with shade. We are seeing more and more clients asking for shade systems and that trend is growing.

The playground of the future will probably need to incorporate more GFRC (Glass Fiber Reinforced Concrete) to render a more natural looking structure (simulating rock, wood, straw, water ... anything that appears to come from the natural world and mix that with the climbing and upper body elements that are in common use today.

With the use of GFRC integrated with the metal climbers and upper body components, and total coverage from the elements by large pavilions or canvass type shade structures, the playground of the future will probably not be much different from what we are seeing today. Can they be made to last 100 years? Yes, but there will always be maintenance and repair issues.

Add new comment