Is Old Man Winter Shredding Your Skate Park? How to curb the effects.

Just last week, I was speaking to a parks director in the Northwest who was almost on the verge of tears. He couldn’t believe that his new skate park, which had been so carefully designed in the summer and so lovingly poured in the fall, was now showing signs of serious damage after just one winter.

How do you prevent winter from damaging your skate park? While the best solution is a solid program of regularly scheduled inspections and maintenance, there are a few extra steps to take before winter sets in. Specific areas of focus vary depending on the surface and structure of each skate park, whether steel-surface, concrete, or composite (Skatelite surface with wood or steel structure).

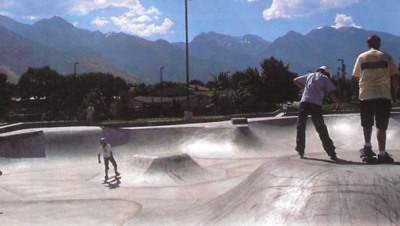

Concrete Skate Parks

Concrete parks, whether poured-in-place or pre-cast, stand up remarkably well to cold winters. Most damage is due to the expansion and contraction caused by the freezing and thawing of the concrete. Poured-in-place parks are more vulnerable, as the concrete is in direct contact with the frozen ground. Pre-cast concrete parks are insulated from the ground by footings or aggregate, putting less strain on the surface.

With both types of concrete parks, make sure the skating area is cleared of any trash or debris—especially around drains and gutters. Anywhere that water might pool and freeze must be kept totally clean. As the snow melts into the water, park drainage becomes crucial. Any water that can’t escape the park may pool and reform into ice puddles, which could cause substantial damage.

With expansion and contraction, concrete can grow or shrink one-eighth of an inch every 30 feet. Even carefully placed crack control lines don’t always work. Brad Siedlecki of Pillar Designs, a leading skate park design firm based in Tempe, Ariz., makes sure to account for these stresses and strains during the design phase. His experience designing the DC skate plaza in Kettering, Ohio, taught him to respect the power of winter weather.

A concrete park I visited last rainy season had a damaged section where a crack ran from the deck down to the transition slope. Water had seeped into the deck crack, and then drained out the transition crack, leaving a stain of minerals. After inquiring I discovered the park had been poured by a local contractor who didn’t understand the strict tolerances of skate park design and construction.

Some pre-cast concrete components have a semi-flexible grout between them, allowing the concrete to expand without causing cracks. Paul Koop of Barkman Concrete, a manufacturer of pre-cast skate park components, says that the harsh Winnipeg winters convinced Barkman’s R&D team to use a pre-cast concrete almost twice as hard as poured-in-place parks.

With both types of concrete parks, any cracks, chips or pits should be cleaned out, smoothed, and filled by traffic grade caulk. The coping should also be thoroughly checked for any chips or holes. Any copying damage should be repaired with spray foam or caulk.

Wood or Steel Structures

I also get a fair amount of calls from park directors with above-ground fabricated parks, whether with wood or steel structures, most with Skatelite surfacing. Even though these parks are insulated from the freezing ground by a slab, they still face winter problems.

Although some steel-surface parks market themselves as “maintenance-free,” many parks and recreation directors discover a different situation in the field. Steel parks can be the most vulnerable to winter damage, due to the large surface area of steel that can corrode and rust wherever the surfacecoating has been ground off.

The constant moisture of winter turns any small scrape into a big issue for steel parks, which have such a large exposed area of vulnerable steel. BMX bike pegs and pedals, skateboard trucks, and even zippers can grind off any powder coating or surface treatment, leaving the steel exposed.

Composite skate parks, made of steel or wood structures with Skatelite Pro surface, are typically very resistant to winter damage. Again, water is the enemy. Any cracks or flaking areas on the surface need to be cleaned, smoothed, and filled with a traffic-grade caulk.

In steel-structure composite parks, the steel is vulnerable to corrosion, unless galvanized over any cuts or welds. Many manufacturers use pre-galvanized steel and apply powder-coating over welds and cuts, which provide little protection against skateboards and BMX bikes. Prep, prime, and paint problem areas with zinc-rich, galvanized paint—for best results.

Wood structure ramps, while more vulnerable than steel, can withstand the winter if the structure is made of high-grade, treated lumber. TrueRide, a Minnesota-founded company experimented with various wood treatments before discovering the preservative Alkaline Copper Quaternary Ammonium (ACQA), which protects lumber without harmful chemicals.

Any park maintaining a solid quarterly maintenance program should have little problem with preparing for winter. While your skate park’s manufacturer should provide guidance on how to repair scratches and gouges, a good rule of thumb is to prep, prime, and paint all trouble spots before winter. Regular maintenance can make sure that small problems don’t grow into big expenses.