How to protect it during installation

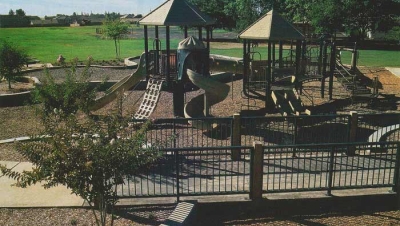

What would a modern playground be without the invention of plastic? I would challenge anyone to find a commercial playground that isn’t fabricated, in part, out of plastic. The range of components made with plastic is never-ending: slides, play panels, roofs, the PVC coating on handholds and other steel parts, and of course you’ll find plastic on decking. Basically, playgrounds are structures made of steel, wood, aluminum, and plastic.

Respect for these materials starts long before the equipment is shipped. What happens to the materials after they leave the factory is sometimes a gamble. Here are some tips on caring for the plastic on your playground equipment from the time it leaves the factory until opening play day.

It is best to remember that even though most playground equipment comes to the end users unassembled, all parts are finished products. That is to say, no one from the factory is coming with the equipment to make certain the plastic stays looking new after it leaves the factory. If plastic components are dragged across the ground, hacked with utility knives or other tools, or jostled around in the back of a semi-trailer; you have just damaged your “finished product.”

Extra care should be taken to ensure your plastic stays in prime condition during shipping and installation. This means that during the process of unloading, storing, and assembling plastic playground parts, you should use tarps, blankets, or other soft materials that will not scratch or gouge your plastic. The packing materials that come off the truck are usually sufficient. Care should be taken when unpacking so that knives do not scar, pry bars do not gouge, and forklifts do not take a bite out of your plastic. Leaving packing material on a piece of plastic until it is actually installed is a simple yet very effective way to protect your investment.

A common occurrence for rookie installers is to roll a big one-piece spiral slide across the asphalt, grass, or dirt. This causes nicks in the products and a place for dirt to start working its way into the nicks making the plastic look old before it’s even installed.

Yes, you can repair minor plastic damage. But you want to be sure you have the skills to perform a repair because if you don’t know what you are doing, you could damage the product even more. Plastic repair takes patience and skill. For example, if a PVC-coated deck has small damage on a corner where it rubbed during shipping, I recommend first taking note of the damage when unloading the truck and noting it on the bill of lading. Next, I would recommend contacting the manufacturer. They often will supply a PVC repair kit with the playground or can send one to you. Make sure you follow their instructions.

Another method of repair for nicks on plastic is using a butane torch. When the damaged area is heated just slightly by moving the flame in a circular motion over the damaged area, you can use a steel putty knife or scraper to mold the plastic back into its original form. Be careful not to overheat the area as you may pop a hole clear through the entire piece. Successfully heating plastic just enough and in an even distance around the damage requires paying careful attention and a thorough understanding of how much heat is just enough to do the job.

Considering the fact that your customers purchased a new playground–not a used one—the best way to have a beautifully finished playground once the installation is complete is to avoid needing to heat and repair it. Take pride in your work and respect plastic by taking special care throughout construction–from unloading to the playground’s opening–to keep plastic components from damage in the first place.